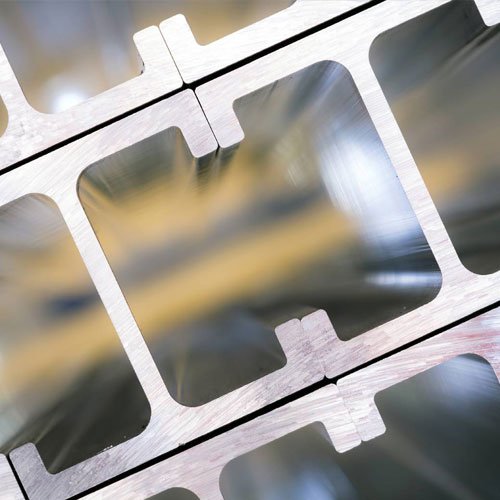

At Solitaire Steel & Engineering LLP, we provide a comprehensive range of aluminum alloys in various temper designations, ensuring the material is suited for its intended application. Aluminum alloys are divided into two main categories based on how their mechanical properties are developed: non-heat treatable alloys and heat treatable alloys.

+91 9819046580

solitairesteelllp@gmail.com

These alloys achieve their strength through cold working processes such as rolling or extruding. Known as work-hardened alloys, their temper is designated by the letter “H.”

These alloys gain their strength through heat treatment followed by cooling and natural or artificial aging. Tempers for heat-treatable alloys are designated by the letter “T.”

| Term | Description |

|---|---|

| H1X | Work Hardened |

| H2X | Work Hardened and Partially Annealed |

| H3X | Work Hardened and Stabilized by Low Temperature |

| H4X | Work Hardened and Stoved |

| Code | Description |

|---|---|

| H111 | Some work hardening due to shaping, but less than H11 temper |

| H112 | Tempered by shaping with no special strain-hardening control |

| H321 | Strain-hardened less than required for H32 temper |

| H343 | H34 temper specially fabricated to resist stress corrosion |

| H116 | Special corrosion-resistant temper for marine applications |

Solitaire Steel & Engineering LLP offers a variety of aluminum alloys tailored to specific temper requirements for both heat-treatable and non-heat-treatable applications. Our team ensures the right temper is selected to meet the mechanical properties necessary for your project.

❝

For more information about aluminum tempers and choosing the right alloy for your needs, visit our, visit our Aluminum Tempers Page or contact us directly.

❞

Mobile : +91 9820525505

Mobile : +91 9819046580

© 2024 Solitaire Steel & Engineering LLP. All rights reserved. Designed by Vebiotic Web Solutions Marketing by Adinads